I DREAM OF AUTUMN

Before moving to Florida, I remember speaking on the phone with a friend, a born-and-raised Floridian, inquiring about pertinent tidbits of information one might want to know before moving to The Sunshine State. I remember her telling me one thing in particular rather clearly, and mostly because I just didn’t believe her! She said, “Amber, once you’ve lived in Florida for a while, you’ll get to a point where you will literally crave, and fully relish, cold weather!” Now, mind you, when she told me this, I was a born-and-raised Arizonan, currently living in Phoenix.

You know that saying: “It’s so hot, you could fry an egg on the pavement!”? I’m almost certain that phrase was invented by someone from Phoenix! I mean, with summer heat easily hitting triple digits in the teens and twenties, in “The Valley of the Sun”, as it’s called by locals, you literally CAN fry eggs on the pavement! Even still, when my friend told me I’d actually crave cold weather, I laughed in disbelief! This was ME she was talking to... A self-proclaimed “desert rat”; I LOVED summer and the heat it brought with it! I thought to myself, “There is no way I will ever yearn for chilly days!”, but little did I know, she was 100% RIGHT!

I think it drives every Arizonan a little bonkers when out-of-towners classify the heat in terms of being any less miserable by saying, “Well, at least it’s a dry heat.”; as if somehow that makes it better! Hot is HOT, and when you get off that plane, or out of your air-conditioned car, and that 120-degree weather hits you like a ton of bricks, the fact that “it’s a dry heat” isn’t the first thought that comes to mind! It feels as if the chasms of the earth have opened up, exposing the gates of Hades themselves, and those who are native to Southern Arizona wouldn’t have it any other way! That’s precisely why I laughed when I was told I’d crave cold weather; I simply found the statement to be impossible! However, after living in Florida for almost 4 years now, I realize I’ve got a giant piece of humble pie to eat!

As much as the Arizonan in me hates to admit it, there really IS some truth to the whole, “dry heat/humid heat” thing (I can hear the lynching party heading my way from Arizona now!). Humid heat is just so... THICK! It just hangs there, completely stagnant in the air, making 95 degrees feel like 195! It’s so heavy and suffocating, things like shade become nothing more than dirty tricks; there’s just no escaping it. It would be more tolerable if it were just a little less relentless, but I learned very quickly upon moving to Florida that the “inside joke” of, “Hey everyone! Winter will be on these 3 days this year.”, is actually far more accurate than it is a joke! And so, I must eat crow and concur... After you’ve lived in Florida for a while, you really do crave the chill of autumn, or a frosty bite from Old Man Winter. This is only temporary though... I’ve also learned that being a Floridian means you grow intolerant to cold weather too. While visitors from Pennsylvania are frolicking the beaches here in mid-January, loving every sun-drenched minute of it, Floridians are shivering under a thick blanket on the sand, watching in bewildered amazement and worry for a friend who’s apparently lost her mind (This is a true story!).

But what exactly does this “tale of two states” have to do with soap making? Oh, that’s easy... It’s the theme of this week’s blog! You see, I believe every soap maker has this “internal clock” when it comes to soap making. You’ll be loading up your online shopping cart with fruity, beachy, or tropical-type fragrances, and designing soap batches with bright, summery colors one week, then the following week... BAM! It hits you like lightening! Seemingly out of nowhere, you suddenly find yourself craving soaps scented in spicy-sweet cinnamon, cozy honey, brisk pine forests, or pumpkin desserts! I don’t know how it happens or what subliminal event triggers it, but for me at least, there’s this total inspirational “switch” that takes place. Without fail, it begins at the very first hint of each season’s changing, and I know it’s begun when I suddenly crave one specific thing: BEER... Soap, that is!

My friend was right... There’s a certain point during the Florida summer when I’ve had enough of the thick humidity and I’m ready for cooler temperatures. I’ve totally reached that point! While it’s still oppressively muggy during the day, the late night and early morning hours are just barely beginning to carry a whisper of chilly air, and all I long to do is wear a sweater... Heck, I’ll even settle for a long-sleeved shirt at this point! My inner craving to make a batch of beer soap tells me fall is on its way (eventually!), and who knows, maybe I can even summon its arrival faster if I delve into fall projects now; sort of like my own version of a soapy rain dance!

While beer soaps themselves aren’t a seasonal thing, they’ve become somewhat seasonal for me. I’m not sure why, but beer soaps have always sold better for me in the fall, so that’s mostly when I make them. They’re also a personal “special treat” on a creative level too, since I definitely have to be in the beer-soap making mood. I have to mentally prepare myself before starting a batch because, well, beer and lye can get a little stinky when first combined to make a lye solution. It’s not a treacherous odor by any means (And not nearly as pungent as boiling the carbonation and alcohol out of the beer!), but it’s not very pleasant either. It’s the result of lye scorching the natural sugars, yeast, hops and barley in the beer, but the scent this creates always cures out by the end of 4 weeks. The finished soaps are so worth the initial and temporary wet-dog-type odor, but admittedly, I am a little sensitive to it. No matter how well-ventilated my workspace is, it always seems to give me quite the headache, but I love beer soaps so much, it’s a nuisance I willingly put up with!

This time, however, I decided I wasn’t going to let anything get to me! I intended for this batch of beer soap to be my official “fall welcome”, and if there’s one thing I know about overcoming obstacles, it’s that if there’s a problem to be faced, there’s usually a solution to it staring right back at you! Please join me in making a fabulous batch of “Honey Barrel Beer Soap”, and in the process, I’ll show you how to make the world’s most UN-stinky-est batch of beer soap ever! That’s a pretty tall statement, I know, but if you’re like me and are prone to getting “beer soap headaches” too (or just aren’t keen on the scent), keep reading! I’m delighted to share with you how to say “goodbye” to stinky beer soap for good!

OF BEER AND BRIGHT IDEAS

I usually always have prepared beer, ready and waiting in the freezer for my next batch of beer soap. By “prepared”, I mean that I’ve already removed the carbonation and alcohol from the beer, it’s frozen (or slushy) and ready to go! All I need to do is remove the specific amount I need for my recipe, then return the remaining beer to the freezer. I prepare my soap making beer in big batches so I don’t have to do it often... It’s a pretty stinky process too! I enjoy using lagers in my beer soaps, but any beer of your choosing will do just as great, especially pilsners and ales.

To remove both the carbonation and alcohol from beer in preparation for soap making, you can choose to either leave the beer opened and exposed to air for several days, until it goes flat and the alcohol naturally evaporates out (A much less stinky process!), or you can choose to boil the alcohol and carbonation out. For this method, simply bring the beer to a steady, rolling boil for about 20 minutes. To help reduce the odor beer and lye give off when first combined, it’s recommended to add the lye to the beer while it’s in a frozen or slushy state. The colder the beer, the less severely its natural sugars and ingredients are scorched by the lye, helping to reduce that unmistakable beer soap odor. When incorporating beer into a cold process soap recipe, you can choose to substitute all of the water in your recipe for beer, or part of it. For this specific recipe I substituted half of my recipe’s total water weight for beer, but how much you’d like to incorporate into your recipe is entirely up to you!

Normally, I enjoy adding beer as my full liquid weight in my recipes, meaning I’ll substitute my recipe’s entire water amount for beer, then dissolve my lye directly into the prepared, frozen (or slushy) beer to make my recipe’s lye solution. This time however, I had a goal and a bright idea, so I decided to do things a little different. Lye needs at least its own weight in water, or liquid, to fully and safely dissolve, so I decided I’d substitute half of my total water amount for beer. The other half would remain as distilled water, and this is what I’d dissolve the lye into.

There was a method to my madness, and my thought process was this: I thought to myself, “Self, why is it that sodium lactate is added to cooled lye solution?”. The answer to that question was an easy one. Sodium Lactate is added to lye water that has cooled to 120 degrees Fahrenheit, or less, so that the lye doesn’t scorch the sodium lactate (Sodium lactate being a salt solution derived from the fermentation of natural sugars within beets and/or corn.). This got the wheels turning in my head. If sodium lactate is added to cooled lye solutions to prevent scorching, why couldn’t I just incorporate the beer to cooled lye solution as well? Surely this would prevent the lye from scorching the natural sugars, yeast, hops and barley in the beer, and as a result, prevent that unmistakable beer soap stench too. It was worth a shot!

The plan was to divide my recipe’s total water weight in half, then incorporate and dissolve the lye into the distilled water portion only. Instead of dissolving lye into frozen beer, I would allow my prepared beer to come to room temperature, then incorporate it into my lye solution once that came to room temperature as well. But then I got to thinking a little more... Certainly as soon as I incorporated the beer into the room-temp lye solution, those natural sugars within the beer would still undergo a thermal reaction from the lye, causing the solution to heat up, and put me right back at square one with stinky beer soap, right? I eventually came to a solution for this too!

I specifically wanted to incorporate the beer into my cooled lye solution while the beer was at room temperature so I could prove to myself that the use of frozen or slushy beer wasn’t necessary (Just think of all the time this would save me by not having to freeze, refreeze, and partially defrost beer every time I wanted to make a batch of beer soap!), and I always pop my lye solution into the freezer anyway to get it to cool down faster. Why not just chill my lye solution a little longer? Instead of pulling my lye solution from the freezer when it’s at, or around, room temperature, like I normally do, why not just keep it in there a little while longer, until the container becomes cool to the touch of a gloved hand? It was settled... That’s precisely what I’d do, all the while, hoping for the best!

MAKING HONEY BARREL BEER SOAP

The design of this soap is simple, beautiful, and supremely fun, with soap frosting and/or melt & pour embeds being completely optional. Of course, a great honey-based soap design begins with an amazing honey-based fragrance oil, and I had just the one in mind for this particular project! Nurture Soap’s “Bergamot and Honey” fragrance oil is an absolute winner through and through, in both scent and performance, as well as in application! No joke, I have one remaining bar of soap that I saved from a batch made a year and half ago that still smells as fragrant, potent and deliciously fresh as the day it was cut! Its notes of juicy bergamot are crisp and vibrant, with a refreshing quality that makes my taste buds tingle, and its complimenting tones of authentic, golden honey are positively sensational! Sweetening and smoothing bergamot’s tartness, the honey note in this aromatic sensation makes this fragrance a year-round hit, as well as an excellent scent for all kinds of soapy themes- including beer soap!

For the optional “high-top” design of this project, I chose warm colors to accentuate the cozy goodness of “Bergamot and Honey” fragrance oil’s wholesome honey accords, and made melt & pour embeds using Nurture Soap’s Low Sweat, Clear Soap Base. These would embellish the top of the soap, and included happy honey bees in “Mimosa Yellow” mica, and beer-filled barrels in “Lustrous Brown” mica, which were dry-painted with a little “Fire Cider” mica to accentuate their detail. In impatient anticipation of the arrival of fall, autumnal leaves, colored in the equally autumnal “Fire Cider” mica, made for perfect accompaniments to celebrate the gradual changing of the seasons!

I wanted the soap frosting portion of this soapy project to be white, but not quite as stark-white as titanium dioxide or “Winter White” mica. I was thinking more in line with the frothy-white top of a big, foamy glass of beer, and Nurture Soap’s “Velvet Pearl” mica was the perfect shade of white for exactly that! The design of the main batch itself would mainly feature the sweet, wholesome, buttermilk-like shade that “Rapunzel” mica imparts to cold process soap, with gorgeously cozy-warm accents of “Lustrous Brown”, “Maya Gold” (The perfect shade of golden honey!), and “Fire Cider” micas, swirled throughout the batch with a hanger tool.

THE MOMENT OF TRUTH!

With my sudsy design all planned out, it was time to determine if my not-so-stinky beer soap scheme would work as I hoped it would. Just in case it didn’t though, I did have my trusty bottle of Ibuprofen nearby! My prepared beer (the recipe’s remaining half of liquid), was sitting pretty at room temperature, and when I pulled my cooled lye solution from the freezer, its temperature read just a hair shy of 61 degrees Fahrenheit. I went ahead and stirred in the sodium lactate first, which I use in every batch of soap I make at 3% per pound of oils, then carefully incorporated the room temperature beer next. What happened afterward had me squealing like a pre-teen at a Taylor Swift concert!

The moment I added the beer to the chilled lye solution, its temperature quickly rose from 61 degrees to just a hair under 97 degrees Fahrenheit, thanks to the sugar content in the beer. I had a quick moment of worry, as I wondered just how much hotter the lye solution would get. But then, just as quickly as it rose, the temperature stopped right there, then began to gradually and steadily decrease! For obvious reasons, I wasn’t about to stick my face over the container and take a big whiff to see if I could catch that telltale odor of a beer-based lye solution, but I really didn’t need to!

Usually, with a beer-based lye solution, that undeniable “wet dog” odor is so all-consuming, I’ve already had to pop 600mgs of Ibuprofen to stave off the pounding headache its induced, and I can easily detect it in my soap batter (as well as in the soap bars themselves for up to 3 to 4 weeks into cure). In this case however, I smelled absolutely NOTHING!! No “Eau de Wet Fido”, no splitting headache, and no odor within the soap batter either! As I poured the batter into portions for my accent colors, the ONLY thing I could smell was the citrusy-refreshing, honey-sweet awesomeness of “Bergamot and Honey” fragrance oil, completely unhindered, and in zero competition with what’s normally a pretty stinky lye solution! Somehow, I’d done it... I had found a way to make beer soap, WITHOUT the beer soap stink!

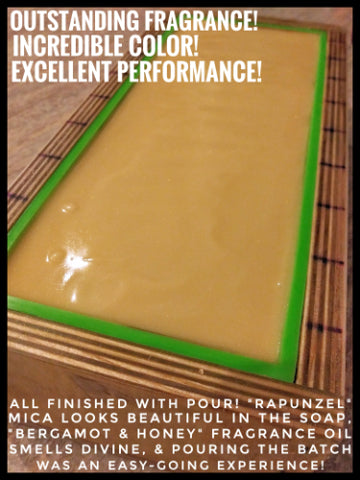

As if I couldn’t have been any more pleased with this soap making experience, “Bergamot and Honey” fragrance oil performed like an absolute dream in this cold process beer soap recipe, and smelled sensational! I was able to execute a hanger-swirl design within the soap with ease, the mica colors looked stunning in application, and “Rapunzel” mica brought the whole comfy-cozy theme together perfectly! The soap gods had indeed played nice... This time!

As I finished piping the top of the batch with my favorite soap frosting recipe, I couldn’t help but add just the slightest touch of shimmer! I didn’t want to overload the batch with too much sparkle, but a light dusting of “Nurture Soap’s “Gold Enigma” mica was just the thing this project needed to add an elegant effervescent-like sheen to the top of the soap! It reminded me of the subtle, golden effervescence of a big, foamy head of beer, tickling your nose as you enjoy an icy-cold brew! Once each decorative soap embed was placed on top, it was time to get the batch insulated overnight. Beer soaps in particular can get pretty dang warm during saponification (This batch got downright hot!), so I was careful not to over-insulate. Simply placing the batch in my un-warmed oven, with the door cracked a little, was all the insulation this batch needed.

NOTHING VENTURED, NOTHING GAINED!

When I first hatched this crazy idea for a “no-stink” beer soap, I had no idea if it was even going to work. One thing’s for sure though, I would’ve never known if I hadn’t at least given it a try. I would’ve still been repeatedly freezing, defrosting and refreezing my supply of soap making beer, trying to rush through beer soap projects as quickly as possible in an effort to escape the inescapable odor, and continuing to spend a small fortune on over-the-counter headache medicine! If you love the idea of beer soaps, but simply dislike the odor that beer and lye emit when combined, or positively loathe that wet dog smell your cut soaps produce for weeks before finally being able to smell their true fragrance, please feel free to give this method a try in your own beer soap batches! Another upside to my no-stink beer soap method: If you love making beer soaps, but have avoided using many of your favorite fragrances because they just wouldn’t go well with a beer base, this method could very well be the solution, since it prevents any noticeable odor in raw soap batter, as well as in the finished soaps themselves. Alternatively, if you’ve ever felt limited in the fragrances you can use in a beer soap recipe, the possibilities become limitless... ANY fragrance will go beautifully in a beer-based soap recipe with this method!

Currently, as I write this blog, I’m sitting outside, laptop in tow, in the fabulously cool night breeze! Perhaps channeling some autumnal vibes through this soap making project really did work as sort of a “soapy rain dance”, bringing this wonderfully refreshing weather my way! On the other hand, there also seems to be a hurricane currently skirting up the coastline of Florida, so I might’ve gone a little too far with this whole “weather wishing” thing!! It’s exactly as the saying goes: Be careful what you wish for; you just might get it!! As for you, my fellow, amazing crafters... May all your wishes for fabulous soap batches always become a reality, and may they always be creations that make you feel exceptionally proud of your incredible talent! When a problem gets in your way, or makes you feel enlightened to discover a new and better way of doing things, may you always feel inspired to put your ideas into practice, never feeling hesitant to take risks or face challenges; rather, embracing them head-on and wholeheartedly!

AMBER’S “NO-STINK BEER SOAP METHOD”, SIMPLIFIED:

Calculate your recipe’s total liquid weight to be half distilled water (or another alternative liquid of choice) and half beer (carbonation and alcohol removed via preferred method). Make sure the distilled water portion is equal to, or greater than, the weight of lye your recipe calls for. Lye needs at least its own weight in liquid to properly and safely dissolve.

It’s preferred to use room temperature, or only lightly chilled beer (not frozen). Dissolve lye in distilled water portion only. Reserve beer for later. Place lye solution in an ice bath or freezer until lye solution becomes chilled, and outside of container feels cold to the touch. Carefully add room temperature (or lightly chilled) beer directly to chilled/cold lye solution and stir well to incorporate. Temperature of lye solution will rise once beer has been added, but will not become hot enough to scorch ingredients within the beer.

Allow lye solution to cool to usual desired soap making temperature, if applicable (lye solution should be under 100 degrees Fahrenheit after beer has been added). Proceed as you normally would when making cold process soap. Enjoy a stink-free soap making experience, as well as freshly-made soap batches which do not have that unmistakable beer soap odor!

SOAP RECIPE:

- Sodium Hydroxide (Lye) @ 5% Superfat

- Liquid @ 33% Lye Concentration (2:1/Liquid: Lye) *Half of Liquid Weight = Distilled Water, Half of Liquid Weight = Beer- Carbonation & Alcohol Removed

- 35% Refined Olive Oil

- 28% RSPO Palm Oil OR RSPO Palm Shortening

- 27% Coconut Oil

- 10% Castor Oil

- 6% “Bergamot and Honey” Fragrance Oil

- 3% Sodium Lactate (Optional)

- 1tsp/PPO: “Rapunzel”, “Lustrous Brown”, “Maya Gold” & “Fire Cider” Micas

SOAP FROSTING RECIPE:

- Sodium Hydroxide (Lye) @ 5% Superfat

- Distilled Water @ 33% Lye Concentration (2:1/Water: Lye)

- 35% Refined Olive Oil

- 28% RSPO Palm Shortening

- 27% Coconut Oil

- 10% Castor Oil

- 2tsp/PPO: “Velvet Pearl” Mica

- “Gold Enigma” Mica (Dusted on Top)

- Melt & Pour Bee Embeds in “Mimosa Yellow” Mica

- Melt & Pour Leaf Embeds in “Fire Cider” Mica

- Melt & Pour Barrel Embeds in “Lustrous

- Brown” Mica (Dry-Painted with “Fire Cider” Mica)

- Wilton #1A Round Piping Tip