LET THE GOOD TIMES ROLL!

Laissez les bon temps rouler is a famous French motto in New Orleans which means “let the good times roll”! On a personal level, when it comes to soapmaking, one of the best ways to get those good times doing summersaults is by making a batch of beer soap! Beer soaps have always been year-round popular sellers for me, but I’ve noticed there’s something about the changing of the seasons to colder weather that amplifies their appeal even more so! As the days slowly grow cooler (I live in Florida, so emphasis on the word “slowly”!), I begin to feel the inspirational “pull” to make more beer soaps myself, so for this blog post, I decided I’d go ahead, let those good times roll, and give in to creativity’s call! After all, an incredible woman and amazing crafter recently told me, “Creativity knows no sense of time. It appears when it wants to.” -Carrie Thornsbury, CEO - Nurture Soap Inc. I couldn’t have said it more perfectly myself!

Beer soaps in general are a touch more particular than the more standard cold process soap recipe is in that there are some fragrance oils which just translate better than others in application when paired with a beer base. In respect for the creative process itself though, there’s no actual “rules” which apply (you’re free to use any fragrance you wish with any soap recipe), but just as a general guideline (and well-meaning advice), fragrances which pair best with a beer base include those which are rich, warm, cozy, spicy, herbal, woodsy, earthy, masculine or gourmand. Fragrances with rich, deep complexity usually pair wonderfully with a beer base, so I decided that out of all the fragrances I had on-hand, nothing other than Nurture Soap’s “Bourbon Street” fragrance oil would be more perfect for this project!

I don’t want to spoil the surprise about what this incredible aroma blossoms into in cold process soap just yet, but seeing as it was my very first time making soap with this mysteriously complex fragrance oil, I figured I’d share my initial “out of the bottle” impressions as well. This is a fragrance which holds a secret, and I could definitely sense there was a story just waiting to be told here from the very first sniff! I’ve never smelled anything quite like it! If I didn’t know better, and hadn’t had many previous experiences with fragrance oils revealing their aromatic “hidden treasures” within cold process soap before, I might’ve taken one sniff of this fragrance oil from the bottle and decided it wasn’t for me. I would have been utterly and completely WRONG! Thankfully, a true “blossoming beauty” usually has some pretty telltale signs that layers exist within it just waiting to emerge, and this fragrance oil had all of those signs! First was its complexity… Notes which “spoke to me” upon first sniff, only to be replaced by another note, and then another with each subsequent sniff. Each time I smelled it, I caught little hints of something else. The second telltale sign was its predominately smokey top note, which when applied to a cotton swab and allowed to dry, revealed a base of something alluringly sweet! Without a doubt, this was a fragrance with a wonderful secret to tell, and my beer soap and I intended to hear all the juicy details!

GETTING BEER READY TO BECOME SOAP

If you’ve never made beer soap before, there’s one important thing you should know…Beer contains both alcohol and carbonation, and unfortunately, lye doesn’t get along with either of these things. In my experiences of both using and enjoying beer soaps over the years though, I can personally confirm that beer soaps have incredible lather, and feel absolutely amazing on the skin, so the process in which one must remove said alcohol and carbonation from the beer is totally worth it! There’s two ways to do this: the slow way (leaving open containers of beer left out for the carbonation to eventually go flat and the alcohol to slowly evaporate over the course of a few days) or the fast way. I’m an impatient soap maker, so I’m going to do this the fast way!

For this project, I used an American lager, but any beer you have on-hand will do. Lagers, pilsners and ales are especially great for making beer soap. Before we begin though, a little forewarning: This process will make your home smell like you threw a raging party, where someone accidentally tipped over a keg and never cleaned it up… seven days ago! So before I begin this process, I always throw a couple wax melts in each of my wax warmers throughout my home and have those going good and strong before I start! That’s the first step. The next step is to take your beer of choice and empty it out into a big pot, then place the pot on your stovetop over high heat.

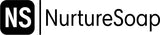

When I’m getting beer prepped for soapmaking, I always make quite a bit more than what I need for the current project because I like to have extra on-hand and ready for the next time inspiration moves me to make beer soap. Even if you’re only prepping enough beer for one batch, make sure to prepare more than what your recipe calls for, as quite a bit of the beer will evaporate during this process. As the beer begins to heat up, you’re going to notice that the carbonation will be the first thing to put up a fight! Your beer will start bubbling and foaming up very quickly.

Don’t let this bubbling and foaming up of the carbonation confuse you with the rolling boil that you want to achieve. As the beer foams up and gets frothy, this is just the carbonation beginning to evaporate off, but the main goal is to bring your beer to a nice and steady rolling boil. Using a spoon, continuously stir the beer as the carbonation increasingly foams up, to prevent it from frothing over. As the beer nears its boiling point, the carbonation will reach its foamy, frothy “peak”, so reduce the heat to medium-high at this point, and continue to stir constantly to ensure the beer stays in your pot- where it belongs!

Once the carbonation has fought its frothy battle (and lost!), the foam and froth will eventually retreat to reveal a beautiful and steady rolling boil… This is precisely what you want to see! It’s now time to boil off the alcohol within the beer, so as soon as you see that rolling boil, you can now set a timer for 15 to 20 minutes, and allow the beer to continue boiling.

Once your beer has maintained a steady, rolling boil for 15 to 20 minutes, you can remove the beer from the heat and allow it to cool down a bit. You’ll notice that the beer looks completely flat at this point, which is perfect! You now have beer you can make soap with… Well, almost!

When it comes to working with beer as an alternative liquid in soapmaking, it’s important to work with it when it’s at a frozen or slushy state. There are a couple reasons for this. First, beer contains sugar, and anything which contains sugar is going to get considerably hotter than liquids which don’t contain sugar once the lye is incorporated. Adding the lye to frozen or slushy beer will help to keep those temps down. Another reason why it’s helpful to work with ice-cold beer is because beer contains, not only sugar, but ingredients like yeast, hops and barley too. Lye doesn’t just love scorching sugars; it loves scorching that yeast too! If you’ve never experienced what that smells like, you’re in for a treat! The beer/lye combination is a profoundly stinky one! Adding your lye to the beer when it’s icy-cold will reduce that stinky-ness factor considerably. For those reasons, once your prepared beer has cooled down a little, it’s ready to be placed in the freezer. I like to transfer my beer from the pot to a freezer bag so that when it comes time to make my soap, I can break off exactly how much I need (or put it in a warm sink-bath for a couple minuets to make it slushy), then put the remaining beer back in the freezer for the next time I want to make soap with it.

EFFERVESCENT EMBEDS & CAPTIVATING COLORS

While I waited for my beer to get ice-cold in the freezer, I got prepped for the rest of the soapmaking process. I absolutely love making high-top soaps, and I’d never actually piped the top of a beer soap before, so I decided now was as good a time as any to do just that! Keep in mind though that if you prefer not to pipe the top of your beer soap, it’s still going to be an incredibly awesome batch of soap! First thing for this high-top design was to get some embeds made!

The vast majority of embed molds I own are actually plastic chocolate or candy molds that I got for a couple dollars at a cake and candy decorating supplies shop. With Nurture Soap’s Low Sweat Clear Soap Base, these molds work great, and make adorable embeds! If you’re looking for an affordable way to make melt & pour embeds, cake decorating shops are a great place to look. If you’re looking to make the best quality embeds to accompany your beautiful, soapy creations, Nurture Soap’s Low Sweat Soap Bases are the bee’s knees! I use no other melt & pour soap bases to make my embeds.

For this project, I chose little bottle and barrel embeds to adorn the top of my soap batch, so I grabbed my trusty .15CC Mini Scoops and two mica colors which would make these embeds perfect for my envisioned design. I’m talking about Nurture Soap’s “Mocha Brown” and “Copper Penny” micas… Ooh la la, are these micas rich and stunning! For the bottle embeds, the warm, deep, cozy hue of “Mocha Brown” mica looked absolutely regal, and the barrel embeds in “Copper Penny” mica positively glowed with this shimmery and opulent shade!

My embeds were complete and looking awesome, so as I continued to wait for my beer to get slushy, I got busy getting my batch colors ready. I had originally planned a 4-color drop swirl design for my “Bourbon Street Beer Soap”, but after looking at those four original colors, I felt like something was missing. I dispersed Nurture Soap’s fabulous “Mocha Brown”, “Copper Penny”, “Maya Gold” and “Winter White” micas in a bit of olive oil, then stood back for a moment to contemplate. It hit me like a ton of bricks! This beautiful combination of colors was missing “Nocturnal” mica! “Nocturnal” mica is the absolute best black mica I’ve ever seen or worked with! I’ve used quite a few different black micas in my day which have turned into more of a charcoal gray-type color in my soaps (forcing me to add more and more to try to achieve a true black shade), but “Nocturnal” mica is as pitch-black as the night is dark, and it doesn’t take much at all to achieve a deep, dark, pitch-black shade in your soaps! I quickly dispersed some “Nocturnal” mica in oil as well, and set it alongside the other colors… Perfection! This was precisely the color scheme I envisioned when I closed my eyes and smelled the elusively complex, rich, smokey aroma of “Bourbon Street” fragrance oil!

A TALE OF LYE AND LAGER

My prepared beer had finally come to a frozen, slushy state, so it was time to make beer soap! When it comes to using alternative liquids in one’s soap recipes, not only are there so many different and fun choices to choose from, but so many different ways in which you can choose to incorporate them too! For example, if you want to make a beer and goat’s milk soap, you can certainly do so! One can choose to substitute their entire liquid amount for a particular alternative liquid, or only part of it. For me, I really love adding aloe juice to my soap recipes, and wanted to incorporate a bit of it in this recipe as well, so I decided to do a beer and aloe juice blend!

After doing a bit of simple math, I calculated my total liquid weight to consist of 75% beer and 25% aloe juice. I did have to round up and down respectively, since my scale doesn’t measure little in-between numbers, so my beer/aloe blend was an approximation of these percentages, but pretty darn close! I also chose to add a pinch of tussah silk as well, and for a batch of this size (32 ounces of oils), half the amount of a regular-size (not jumbo!) cotton ball’s worth is plenty. I absolutely love the silky feel and lather tussah silk imparts to my soaps, and it’s important to me to purchase cruelty-free, humanely harvested tussah silk (the world needs its moths too!), but keep in mind that tussah silk is not vegan, so if you prefer your soap recipes be vegan-friendly, you’ll want to omit the tussah silk.

With my slushy beer/aloe blend weighed out and ready, it was time to get the lye added and make my lye solution. I carefully incorporated the lye and stirred well. Thankfully, incorporating the lye to frozen/slushy beer prevented the solution from getting excessively hot. At its hottest, it reached 141°F, but can you imagine how much hotter it would have gotten had the beer not been frozen? I was also thankful for the fact that my home didn’t smell like a divey bar either! I mean, it didn’t smell awesome, but that classic beer “stank” didn’t permeate my whole workspace either! It definitely pays to make sure the beer is ice cold before incorporating the lye.

Another word of forewarning to first-time makers of beer soap: The very first batch of beer soap I ever made, I was completely disheartened and royally bummed when I excitedly cut my batch only to discover that my soaps didn’t smell very pleasant at all! I didn’t know what I had done to screw things up, or where I had gone wrong, but without a doubt, my soaps smelled exactly like a wet dog! I was mortified, and didn’t know how I was going to offer soaps scented in “Eau de Wet Fido” to my friends and family. Then something magical happened… About 5 or 6 weeks later, that wet dog stench had cured completely out, and I could clearly smell the fragrance oil I had used in my recipe! So, keep in mind that it is completely not uncommon for freshly-made batches of beer soap to smell like Rover just came in from the rain! I’ve found that darker, “danker” beers are usually bigger culprits of this, but no matter which type of beer you use, I promise that wet dog odor WILL cure out of your soaps! If this happens in your batch of beer soap, just keep calm and let cure!

As I finished making my beer-based lye solution, and ensured both my lye and tussah silk fibers were completely dissolved, I set it aside to allow the solution to cool down to around room temperature (carefully placing your lye solution in an ice bath is another option that will help speed this along nicely), then continued by getting my batch oils weighed out and ready to be made into wonderful beer soap!

ONE BOURBON, ONE SCOTCH, ONE BEER SOAP!

Once both my lye solution and batch oils reached about 80°F it was time to get to soapmaking, or as they say in New Orleans, “pass a good time”! After carefully incorporating my beer/aloe lye solution into my batch oils and stick-blending to a nice, fluidly-workable light trace, I divided off my soap batter into four smaller portions for my fancy-looking, warm-toned color scheme, then colored the remaining larger portion with “Winter White” mica. To my smaller portions, the exquisite “Mocha Brown”, “Copper Penny”, “Maya Gold” and “Nocturnal” micas were incorporated, and I couldn’t have been more pleased with how well these colors complimented one another, as well as the overall theme and feel of a beer soap made with “Bourbon Street” fragrance oil!

I proceeded by adding “Bourbon Street” fragrance oil to each portion of soap batter, which by this time, was continuously fascinating me! Just getting it out of the bottle and incorporating it into my soap batter, it was already working its voodoo on me! Something about the way in which this complex and alluring fragrance lingered around my workspace had me fully intrigued, as already, it was revealing aromatic notes that had previously remained hidden from me. An enticing organic sweetness emerged to seduce and entrance my olfactory receptors! As I began pouring my drop swirl design, I was already falling victim to its charm! There’s just something about a deeply complex and mysteriously multifaceted fragrance which catches me, hook, line and sinker every time! Adding even more creative joy to this curiously blissful aromatic experience was the fact that this fragrance oil was also playing so nicely with my beer soap recipe… No ricing, no acceleration; just easy-going, peaceful soapmaking!

As I finished my pour, I was surprised to discover that from the very first moment I incorporated “Bourbon Street” fragrance oil into my soap batter, I could no longer detect even the slightest hint of that classic beer-lye “stink”! I discovered that this multifarious fragrance was the perfect accompaniment to my beer soap recipe! My workspace smelled intoxicating (pun intended!), and the fragrance oil itself had performed beautifully from the beginning of pour to the end of it!

A TALL, FROSTY BEER SOAP!

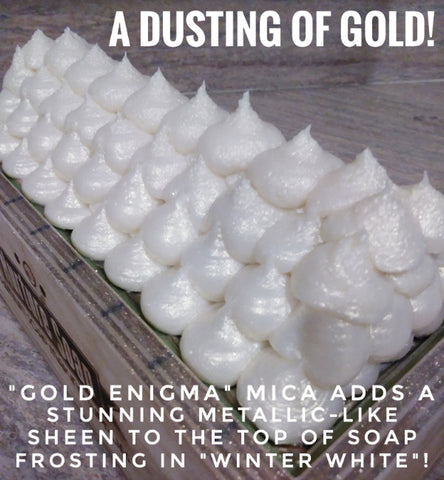

When it came to piping the top of my soap, I knew exactly how I wanted to complete this Big Easy-inspired beer soap design. Now, keep in mind that this step is completely optional, and will in no way take away from, or hinder your own soapy beer creation from being absolutely marvelous if you choose to skip piping the top of your soap batch. When it came to the vision that I had in my mind’s eye though, a big, bubbly, white top to represent the foamy head of a freshly-poured glass of ice-cold beer seemed a fun added touch. Using “Winter White” mica to color my soap frosting, I added big, round dollops of “foam” to the top of my soap loaf. When I was finished however, it seemed to be missing something. The foamy head of an actual glass of freshly-poured beer has a delightful effervescent look to it. As it bubbles up, then slowly fizzes down, it almost seems to glisten-away into oblivion, revealing the golden, hazel-brown beer below it. An EnviroGlitter seemed too large a micron size to convey this aesthetic subtlety, but a mica I always keep on-hand for situations just like this seemed perfect for the job! I grabbed my Glitter Spray Pump filled with the dazzling “Gold Enigma” mica and began spraying away! I can’t NOT take a moment to mention just how much I adore the new design of Nurture Soap’s Glitter Spray Pumps! The shimmery mess I usually leave behind when embellishing the tops of my soaps is greatly reduced with this spray pump. The quality itself is excellent, and it disperses my “bling” with an even precision. As I finished adorning my piped top with an elegantly fine dusting of “Gold Enigma” mica, my soap had metamorphosed into a handsomely eye-catching creation, with a striking, almost metallic-like, golden sheen!

By way of my bottle and barrel embeds, I lovingly placed the last finishing touches atop my shimmery, “foamy beer” of a piped top, and decided it was “last call” for this soapy creation! I insulated the batch, wished it bon voyage, then sent it off to a peaceful night’s rest of saponification slumber!

I’D LIKE TO RAISE A TOAST!

The next morning my beer soap practically unmolded itself! I mean, I literally had to catch it from tumbling, face-down, from my 2.5lb Basic Soap Mold! This was in thanks to two things. First, every impatient soap maker’s best friend… Sodium lactate! Sodium lactate is a salt solution derived from the natural fermentation of sugars found in beets and/or corn. It aids in the unmolding of soap in that it reduces the amount of time one must wait for soap batches to set up and be ready to unmold. I use it in every single batch of soap I make at 3% of my total oil weight, and add it directly to my cooled lye solution, immediately prior to incorporating my lye solution into my batch oils. Sodium lactate is awesome for this impatient soap maker in that most of my batches (with some exceptions) are ready to be unmolded and cut 8 to 12 hours after I’ve poured them.

Another factor which greatly helped to speed up unmolding time was the beer itself! Because beer contains natural sugars, my batch warmed up during saponification and gelled. As a personal preference, I love me a batch of gelled soap! Gelled soap will be firmer/harder from the get-go, and in many instances, also enables colorants to appear brighter, bolder and more vivid within the soap itself!

As I began to cut each charming slice of “Bourbon Street Beer Soap”, I was immediately impressed! I know, I know, you’re probably thinking, “Oh great! Here goes Amber, tooting her own horn!”, but that’s totally not what I mean! What impressed me was the fact that as I cut my batch, I couldn’t detect even the slightest hint of that “wet dog beer soap” odor I mentioned earlier, and usually ALL of my beer soap batches have at least some slight detection of it that eventually cures out. With this batch though, all I could smell was the fascinating “Bourbon Street” fragrance oil, and at this point, I was full-on in love with it! The transformation this fragrance oil undergoes in application is absolutely AMAZING, and in every way, this truly was a fragrance oil with a magnificent story to tell!

Out of the bottle, wood smoke, or a smoky whiskey-type note reigned supreme, but in application… HOLY WOW! I swear I could smell opulent Oudh and warm, woodsy notes! Possibly a whisper of rich suede too! Those dominant smoky notes parted just enough to create a path for notes of malty tonka bean and spicy-sweet tobacco leaf to emerge as well! A gorgeously smooth and dapper scent which I found to be downright sexy! As I smell the bars, now five days old at the time of this writing, even more handsome secrets have been revealed, which I’m sure will be completely unveiled by cure’s end! I am enamored by this scent!

For those who may have never made beer soap before, I hope in some small way I’ve inspired you to give it a try. To go forth as the incredible and uniquely talented crafters you are, and make beautiful batches of bubbly beer soap! Any soap recipe can be converted into a beer soap recipe (just substitute your water for beer!), and will make for a fabulous slice of beer soap! To all my amazing fellow crafters: Santé! Salud! Salute! Proost! Saúde! Or as they say in my little corner of the world: Cheers! May all your soap batches bring you joy, and may the inspiration to try new and exciting soapy creations always find you! Laissez les bon temps rouler my crafty friends!